The working principle of the mold temperature machine

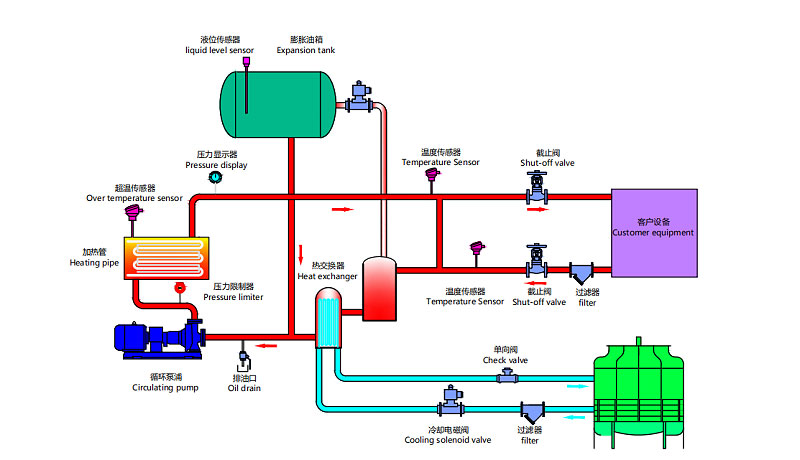

I. Composition

A mold temperature controller is generally composed of the following main components:

Heating Section: Responsible for converting electrical or gaseous thermal energy into heat to warm the medium (such as thermal oil or water). Heating elements (e.g., electric heating tubes) are immersed in thermal oil; when energized, they generate heat, raising the temperature of the thermal oil.

Cooling Section: Primarily consists of a cooling water tank and a circulation pump. When the mold requires cooling, cooling water enters the cooling water tank through pipes, absorbs heat from the thermal oil, and is then pumped back to the mold by the circulation pump for secondary cooling.

Circulation System: Includes a circulation pump and thermal oil circulation pipelines. The circulation pump drives thermal oil to circulate between the mold and the mold temperature controller, enabling heating and cooling of the mold. The thermal oil circulation pipelines connect the mold temperature controller to the mold, ensuring smooth flow of the thermal oil.

Control System: The “brain” of the mold temperature controller, responsible for overall operation and control. It comprises a temperature sensor, controller, and actuator. The temperature sensor monitors the mold temperature and transmits the temperature signal to the controller; the controller adjusts the operation of the heating element and circulation pump based on the difference between the preset temperature and the actual temperature; the actuator, in turn, controls the power output of the heating element and the on/off status of the circulation pump according to the controller’s instructions.

II. Working Principle

The working principle of a mold temperature controller can be summarized into the following steps:

Heating Process: The mold temperature controller first heats the thermal oil via the heating section. After being energized, the heating element (e.g., electric heating tube) generates heat, converting electrical energy into thermal energy and transferring it to the thermal oil, thereby increasing its temperature.

Circulation Process: The heated thermal oil is pumped by the circulation pump through the thermal oil circulation pipelines to the mold, where it heats the mold. After absorbing heat from the mold, the thermal oil cools down and flows back to the mold temperature controller for re-heating.

Cooling Process: When the mold temperature reaches the preset value, the control system stops the heating section and activates the cooling section to cool the thermal oil. Cooling water enters the cooling water tank through pipes, absorbs heat from the thermal oil, and is then pumped back to the mold by the circulation pump for secondary cooling.

Temperature Control: Throughout the process, the control system continuously monitors the mold temperature via the temperature sensor. It adjusts the operating status of the heating element and circulation pump based on the discrepancy between the preset temperature and the actual temperature, achieving precise control of the mold temperature.

III. Advanced Functions

In addition to basic heating and cooling functions, modern mold temperature controllers are equipped with multiple advanced features, such as multi-point temperature control, rapid temperature rise/fall, and complex program control. These functions have expanded the application scope and flexibility of mold temperature controllers in industries like plastic injection molding, enabling finer temperature control tailored to diverse production requirements.